PVC Blow moulding

Blow moulding is a widely used manufacturing process to create hollow plastic products by inflating molten plastic inside a mould, before being ejected from the machine once cooled. PVC blow moulding is a common technique for producing robust products, particularly where strength and impact resistance are crucial.

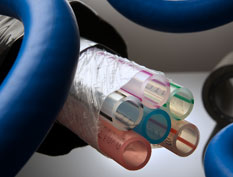

Among the plastics used in blow moulding, PVC stands out for its versatility, durability, and chemical resistance. Dugdale’s PVC blow moulding compounds are ideal blow moulding materials for medium to high-impact applications, making it a preferred choice in many industries.

Blow moulding polymers enable manufacturers to tailor their products' properties, ensuring they meet specific performance requirements. The polymer blow moulding process ensures the creation of consistent, high-quality products, enhancing durability and precision.

Blow moulding is ideal for creating both simple and complex designs, catering to diverse industries and applications.Whether for containers, automotive components, or other specialised items, plastic blow moulding offers the flexibility to design and manufacture with different specifications.

Explore our range of blow moulding PVC materials to discover solutions for your specific requirements. If your project demands a PVC compound with unique specifications beyond our existing offerings, our team is ready to collaborate and develop a custom plastic blow moulding compound that precisely meets your needs. Your vision, our expertise.

Get in touch with our team today to discuss your blow moulding projects uk.sales@benvic.com.