Injection Moulding Compound

Plastic injection moulding stands as one of the most prevalent manufacturing processes, facilitating the production of a vast array of plastic components and products. Its mechanism involves injecting molten plastic material into a mould cavity, allowing it to cool and solidify before ejecting the finished part from the mould.

Injection moulding is widely utilised across industries such as automotive, electronics, packaging, medical devices, and consumer goods. The popularity of injection moulding stems from its myriad of advantages, including unparalleled versatility in part design, remarkable production speed, impeccable repeatability, and the capability to fabricate complex shapes with precision, even within tight tolerances.

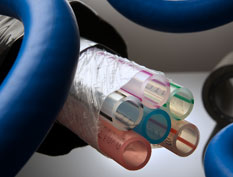

Among the diverse materials employed in injection moulding, PVC emerges as a favoured compound owing to its distinctive properties and manifold benefits. PVC offers exceptional versatility, cost-effectiveness, durability, electrical insulating properties, flame resistance, chemical resistance, good dimensional stability, and recyclability.

At Dugdale, our proficiency in PVC thermoplastics is deeply rooted in decades of experience crafting moulding PVC compounds for a multitude of industries and applications. Leveraging this wealth of knowledge and expertise, our team collaborates closely with customers to select or develop the ideal PVC thermoplastic compound tailored to their unique requirements, whether technical, commercial, performance-related, or environmental.

Moreover, our commitment to customer satisfaction extends beyond consultation; we offer practical support throughout the production process. Our in-house pilot line enables the swift production of sample batches of moulding PVC compounds for product testing, thereby expediting time to market and reducing project costs. Our dedicated colour technicians and specialised equipment ensure precise colour matching, ensuring consistency not only within a batch but also from batch to batch. With Dugdale, customers can expect comprehensive assistance and exceptional results for their moulding PVC projects.